Tailored Designs, Expertly Managed from Start to Finish

Whether you’re looking to enhance an existing product or need R&D support to develop an entirely new solution, we work closely with you from start to finish. You’ll have a dedicated point of contact who will guide you through every step, ensuring that your project is expertly managed and fully customized to your specifications.

Key Benefits of Our Partnered Innovations:

- Comprehensive R&D and Customization: We bring our experience and R&D capabilities to help clients refine and optimize existing products, tailoring them to meet specific operational needs, rather than starting from scratch.

- Deep Collaborative Partnerships: Every custom project is done in close partnership with our clients, ensuring we fully understand your requirements and develop solutions that seamlessly integrate into your workflow.

- Enhanced Efficiency and Cost Savings: Our packaging solutions, such as triple-layered syringe pouches and optimized bottle packaging, reduce handling time and streamline processes, leading to significant time and cost savings.

- Expertly Tailored Solutions: MPS Pharma applies its existing skill set and product line expertise to develop customized solutions that increase workflow efficiency and reduce production costs, ensuring every solution is fit for purpose.

- End-to-End Project Management: From design and development to procurement and validation, MPS Pharma manages the entire custom project, providing clients with a single point of contact who takes full ownership of every aspect of the process.

- Proven Track Record of Innovation: Many of our custom projects evolve into standard product offerings, demonstrating our ability to deliver innovative solutions that not only meet but exceed client expectations.

Proven Partnered Solutions for Compounding Pharmacies: Optimizing Efficiency and Delivering Results

TipGuard Ophthalmic Bottle Cap: MPS Pharma and Medical developed the TipGuard product, an embedded tip/cap solution that improved labor efficiency and aseptic handling for a compounding pharmacy scaling from 503A to 503B operations.

SafeDate™ Low Volume BUD Compliant Ophthalmic Dropper: MPS Pharma and Medical created the SafeDate dropper, enabling a 503A compounding pharmacy to comply with new USP <797> Beyond Use Dating rules without investing in large-scale drug manufacturing equipment.

Large Format Syringe Package: MPS Pharma developed and validated a custom syringe package that significantly improved workflow efficiency in controlled environments through triple-layered packaging.

Ophthalmic Packaging Optimization: By custom packaging ophthalmic components in larger, more efficient quantities, MPS Pharma reduced handling time and costs while enhancing operational efficiency for sterile compounding teams.

Custom Partnership Product Development: Collaborating with pharmacists, MPS Pharma created a tailored solution that met specific filling requirements, evolving into a standard product offering to serve compounding pharmacy needs.

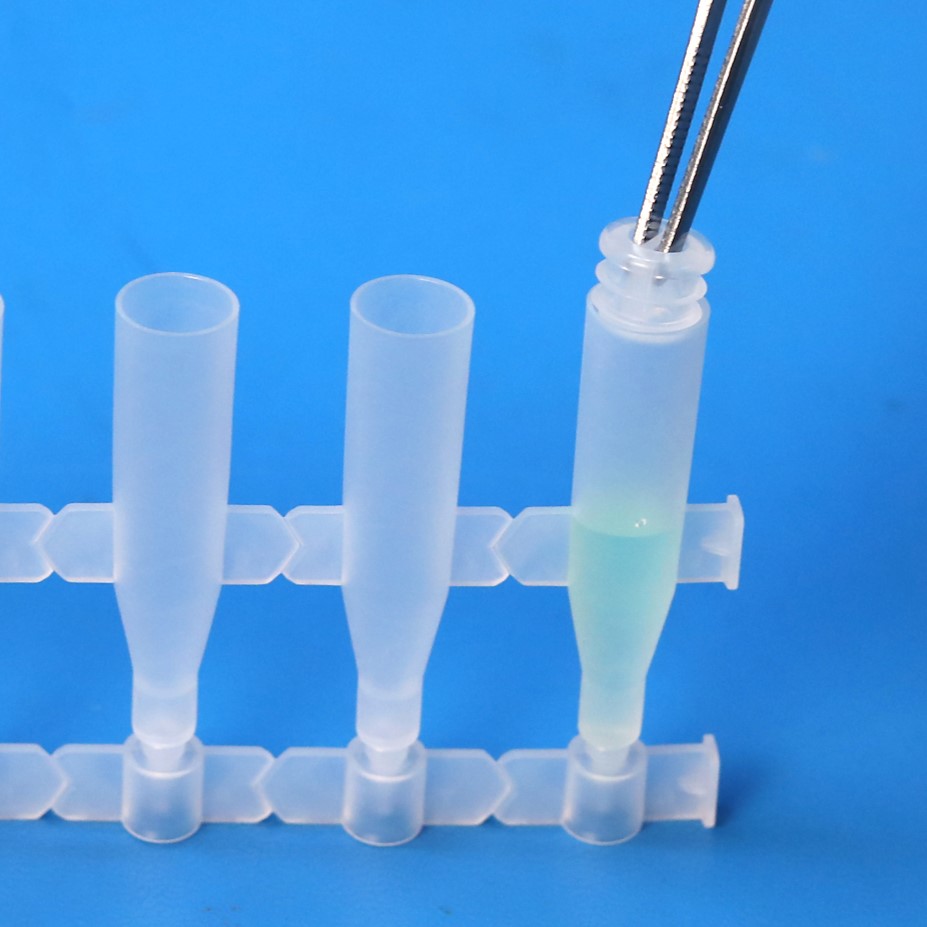

Optimizing Automated Filling with Custom Upright Trays: How MPS Pharma Enabled Seamless RABS Integration for a Growing Compounding Pharmacy.

Have any questions?

Contact our Customer Service team for additional support at

(844) 641-3814 or by email at sales@mpspharma-inc.com

0

0