Case Study:

Ensuring USP <797> Compliance with SafeDate™ Low Volume BUD Compliant Ophthalmic Dropper

Adapting to New USP <797> Guidelines: How MPS Pharma Enabled Compliance Without Compromising Efficiency.

Client Overview

A 503A compounding pharmacy specializing in non-preserved sterile compounds faced a regulatory challenge due to upcoming changes in USP <797> guidelines. The pharmacy sought a cost-effective, scalable solution to maintain compliance and continue delivering high-quality care while adhering to the new compliance guidelines.

The Challenge

The new USP <797> guidelines introduced strict Beyond Use Dating (BUD) rules for non-preserved sterile compounds, limiting BUD to 24/72 hours unless validated with more stringent testing.

Key obstacles:

- Regulatory Compliance: The pharmacy could no longer use MPS’s PureFlow Preservative-Free Bottles without extensive and costly validation processes, as required by their State Board of Pharmacy.

- Cost and Feasibility Constraints: The pharmacy lacked the resources for large-scale blow-fill-seal (BFS) equipment typically used by major drug manufacturers to fill single dose droppers. Furthermore, even if available, the nature of 503A compounding does not allow for this level of scale.

- Operational Continuity: They needed a solution that would allow them to comply with new regulations while maintaining their ability to compound patient-specific prescriptions efficiently.

The Collaboration

MPS Pharma partnered closely with the pharmacy to understand their operational constraints and regulatory requirements. Together, we explored design options that would ensure compliance with the new BUD guidelines while avoiding costly equipment upgrades.

The Solution

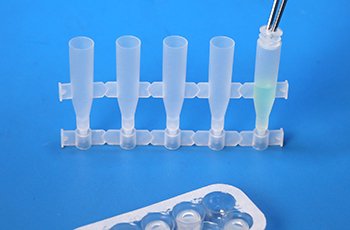

MPS Pharma developed the SafeDate™ Low Volume BUD Compliant Ophthalmic Dropper, an innovative solution designed specifically to address the pharmacy’s challenges.

Key features of the SafeDate design:

- Friction-Fit Cap System: Utilizes a secure design without requiring BFS equipment, ensuring compliance while minimizing costs.

- Multi-Use Re-Closable Cap: Gives the patient an easy to re-close, multi-day usage solution.

- Regulatory Alignment: Engineered to meet USP <797> guidelines for non-preserved sterile compounds, simplifying compliance with State Board requirements.

- Patient-Specific Compatibility: Allows pharmacies to continue their focus on individualized compounding without large-scale production barriers.

MPS oversaw the entire development process, from design to validation, ensuring the solution aligned perfectly with the pharmacy’s needs.

Implementation Process

The SafeDate solution was tested collaboratively with the pharmacy’s team, ensuring it integrated seamlessly into existing workflows. MPS provided detailed guidance on implementing the new system, including compliance documentation to support regulatory inspections.

The Results

- Regulatory Compliance: The pharmacy achieved full compliance with USP <797> BUD rules.

- Cost Savings: Enables pharmacies to use a more cost effective dropper system.

- Operational Efficiency: The SafeDate design allowed the pharmacy to maintain patient-specific compounding without disruptions.

Adapting to new regulations? Let us help you navigate compliance challenges with innovative, cost-effective solutions. Learn more about MPS Pharma’s Collaborative Innovations today.

Have any questions?

Contact our Customer Service team for additional support at

(844) 641-3814 or by email at sales@mpspharma-inc.com

0

0